DIRECTIONS:

To play along and increase your twitter twaffic do the following:

1. Click on my twitter Icon above. Follow me first of all!

2. MAKE A BLOG POST LIKE I am doing. Copy and Paste these directions.

3. Grab the YO Tweeps Twaffic Exchange Button. Put him in your post.

| <a href="http://supahmommy.blogspot.com/2010/03/yo-tweeps-twaffic-exchange.html" target="_blank"><img border="0" alt="" src="http://i148.photobucket.com/albums/s27/dperry_2007/yotweeps-1.png" /></a> |

5. Put a twitter icon / link on your blog post like I did. It should directly link to your TWITTER PROFILE.

6. Visit some other #YOTweeps linkers on the list.

7. Follow them if you choose and shout out to them on twitter that you are following so they can instantly follow you if they're on. (Follow their blog as well if you're interested.)

Example:

@groverwoodworks #yotweeps I'm following!

8. If someone follows you JUST reciprocate. It's that easy.

SPread the word.

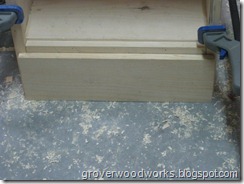

Here is what things look like from the front side. You can see how the Ship Lap slats give it a unique look and feel. One thing to note if you do plan on a project that uses this type of back you will want to paint the individual pieces before permanently installing them. The wood will expand and contract from season to season so those joints through out the year will be different and if they open up and you painted it while it they were close then you will see bare wood. Plus it’s much easier to get in between the joints when they aren’t installed.

Here is what things look like from the front side. You can see how the Ship Lap slats give it a unique look and feel. One thing to note if you do plan on a project that uses this type of back you will want to paint the individual pieces before permanently installing them. The wood will expand and contract from season to season so those joints through out the year will be different and if they open up and you painted it while it they were close then you will see bare wood. Plus it’s much easier to get in between the joints when they aren’t installed.